Zirconium Sheet / Plate

Processing technology of Zirconium Sheet / Plate

The structure of Zirconium Sheet / Plate is closely related to the processing technology. The rolling temperature, deformation and heat treatment system all have influences on the structure, and the rolling temperature is the most important element among them.

During the forming of sheet, special attention should be paid to bite. Rebound tendency and crack phenomenon which is easily caused by nick should also be attached importance.

At room temperature, Zirconium Sheet / Plate with a thickness of less than or equal to 19mm can be bent to a bending radius of five times the thickness using standard forming equipment.

Heating to 260-427℃ can reduce the bending radius and reduce the chance of cracking.

Properties of Zirconium Sheet / Plate

|

|||||||||||||||||||||||||||||||||||||||||

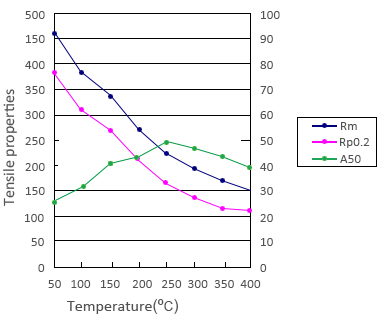

Tensile properties at different temperatures

Tensile properties of industrial Zirconium Plates at high temperature

|

||||||||||||||||||||

Our Zirconium Sheet / Plate products

|

||||||||||||||||||