Hastelloy C-22

Overview of Hastelloy C-22(N06022)

Hastelloy C22 (N06022) is a nickel-based superalloy composed of elements such as nickel, molybdenum, cobalt and tungsten, with a nickel content of approximately 60%.

It is a universal nickel-chromium-molybdenum-tungsten alloy, which has better overall corrosion resistance than other existing nickel-chromium-molybdenum alloys, including Hastelloy C-276, C4 alloy and 625 alloy.

Hastelloy C22 alloy has excellent resistance to pitting corrosion, crevice corrosion and stress corrosion cracking.

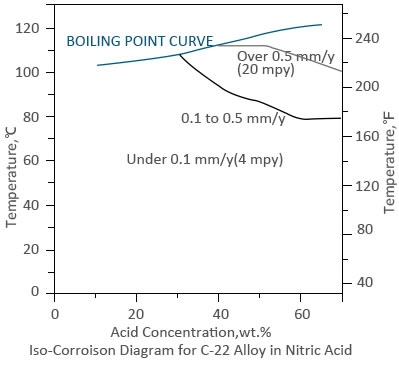

It has excellent resistance to oxidizing water media, including wet chlorine, nitric acid or mixed acids of oxidizing acids containing chloride ions.

Hastelloy C-22 (UNS N06022/W N 2.4602) chemical composition

|

Hastelloy C-22 alloy minimum mechanical properties at room temperature:

|

Hastelloy C-22(N06022) Properties

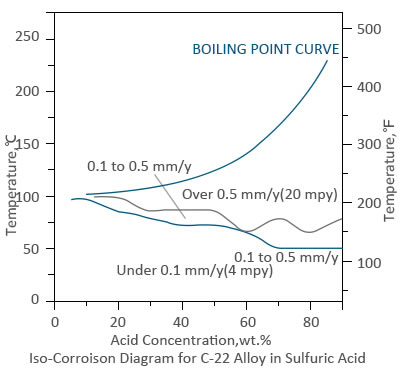

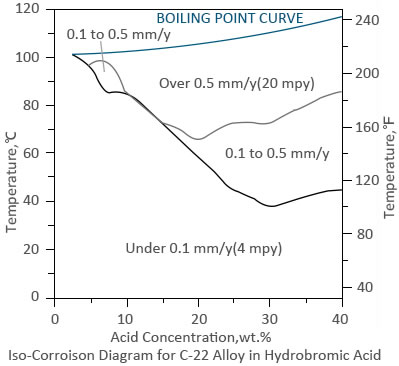

Excellent resistance to pitting corrosion, stress corrosion cracking and uniform corrosion.It is suitable for a variety of corrosive chemical media, including chlorides, sulfides, acidic environments and oxidizing media.

It can maintain high strength and corrosion resistance at high temperatures.

Hastelloy C-22(N06022)Application

Chemical processing: pumps, valves, pipes, heat exchangers and sensors, especially those equipment that comes into contact with corrosive chemicals.

Marine engineering: Components used for manufacturing seawater desalination systems, ships and offshore platforms.

Pulp and paper: Used in the manufacture of bleaching equipment and chemical recovery systems.

Pollution control: Used for manufacturing components of acidic gas washing systems and waste incineration systems.

Nuclear industry: Heat exchangers and pressure vessels used in nuclear power plants.

Food processing: Used for manufacturing equipment and containers for handling acidic and alkaline media.

Marine engineering: Components used for manufacturing seawater desalination systems, ships and offshore platforms.

Pulp and paper: Used in the manufacture of bleaching equipment and chemical recovery systems.

Pollution control: Used for manufacturing components of acidic gas washing systems and waste incineration systems.

Nuclear industry: Heat exchangers and pressure vessels used in nuclear power plants.

Food processing: Used for manufacturing equipment and containers for handling acidic and alkaline media.