Tantalum Target

Principle of Tantalum Target

Tantalum is widely used in electrolyte capacitor manufacture because of its ability to form thin oxides and the protective effect of oxide film. Evaporation method was used in the early stage of Tantalum deposition, but physical vapor deposition method such as sputtering coating method which appeared in the late 1960s replaced evaporation method as a better method for thin film deposition.

Physical vapor deposition is a method in which ionized argon atoms strike a material source called a target material by means of electromagnetic mechanics, thus hitting out of the metal target atom, and then the target atoms will deposit on the substrate to form a layer of film.

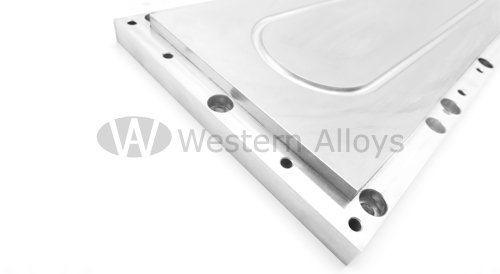

Our Tantalum Target product

|

||||||||||||||||||||