Overview and application of Niobium

Niobium is suitable as the structural material for reactor and coating material for nuclear fuel as well as the thermal protection and structural material adapted in aerospace industry. In the Metallurgical industry, Niobium is mainly used as additive to produce high strength alloy steel, to improve properties of various alloys and to make super hard tools.

Niobium also plays an important role in surgical field, which can not only be used to manufacture medical devices, but also be a good "Biocompatible Material". Niobium can constitute alloys with various elements, which have important applications in various industries.

For example, Niobium Titanium alloy, Niobium Zirconium alloy, Niobium Tin, Niobium Aluminum germanium and other compound superconducting materials are used not only for power transmission, power generation, manufacturing superconducting magnets and controlling nuclear fusion, but also for navigation devices in space aircraft, electromagnetic propulsion equipment for high-speed diving ships and superconducting super-class high-speed trains. Niobium alloy is also an advantageous material which can be used to make components of supersonic ramjet engines.

Niobium also plays an important role in surgical field, which can not only be used to manufacture medical devices, but also be a good "Biocompatible Material". Niobium can constitute alloys with various elements, which have important applications in various industries.

For example, Niobium Titanium alloy, Niobium Zirconium alloy, Niobium Tin, Niobium Aluminum germanium and other compound superconducting materials are used not only for power transmission, power generation, manufacturing superconducting magnets and controlling nuclear fusion, but also for navigation devices in space aircraft, electromagnetic propulsion equipment for high-speed diving ships and superconducting super-class high-speed trains. Niobium alloy is also an advantageous material which can be used to make components of supersonic ramjet engines.

Properties of various Niobium products

|

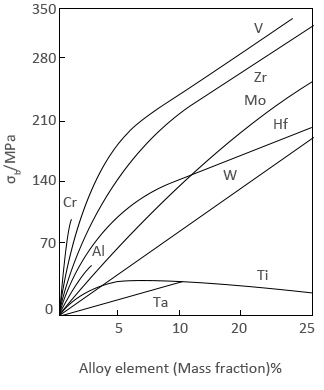

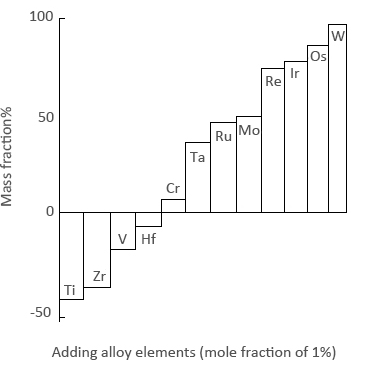

Effect of alloy elements on the ultimate strength of 1095°C recrystallized Niobium

The percentage of Niobium reinforcement obtained by permanent strength tests at 1200°C and σ=140MPa

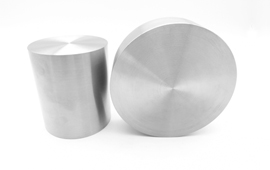

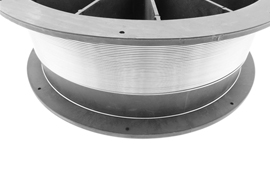

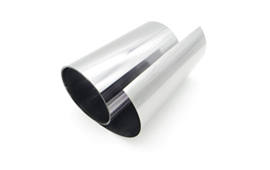

Our Niobium products

Western Alloys has pure Niobium products and Niobium alloy products of various specifications and dimensions.

Our product list includes Niobium Sheet and Niobium Strip (ASTM B393), Niobium Rod and Niobium Wire (ASTM B392), Niobium Tube ( ASTM B394), C103 alloy (ASTM B654, ASTM B655), Niobium Titanium alloys, Niobium Zirconium alloys.