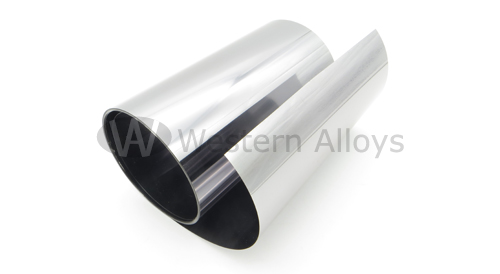

Niobium Foil / Strip

Niobium Foil / Strip processing technology

Electron beam smelting niobium ingots → forging at room temperature (or ≤400 c) → annealing → roughing → annealing → strip rolling → annealing → foil rolling → heat treatment

Niobium Foil can be pressed into Niobium Cup and Niobium Crucible.

Niobium Cup and Niobium Crucible can be used in corrosion resistant chemical industry and synthetic diamond industry, also used for making high pressure sodium lamp.

Our Niobium Foil / Strip products

Western Alloys has pure Niobium Foil / Strip, Niobium Titanium alloy foil / strip, Niobium Zirconium alloy foil / strip, and other Niobium alloy foil / strip products.

All our Niobium Foil / Strip products follow ASTM standard (ASTM B393 or ASTM B654). We can also provide customized products according to customer's special requirements.

Specifications of Niobium Foil / Strip

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

Properties of Niobium Foil / Strip

|

||||||||||||||||||||||||||||