TC18

Properties and applications of TC18 Titanium alloy materials

TC18 is a high-strength Titanium alloy invented by the All-Russian Aeronautical Materials Research Institute of Russia in the 1960s, and the corresponding alloy grade in Russia is BT22.

TC18 Titanium alloy nominal composition is T-5AI-5Mo-5V-1Cr-1Fe, the nominal composition of AI equivalent is 5.0%, Mo equivalent is 11.76%.

GB/T3620.1 Titanium and Titanium alloy grades and chemical composition of TC18 Titanium alloy chemical composition. The alloy has approximately equal amounts of α phase and β phase in the microstructure under annealing state, which is the highest strength Titanium alloy under annealing state.

TC18 Titanium alloy can be welded by various welding methods, and the annealing has good welding performance. The normal operating temperature of the alloy is 400℃.

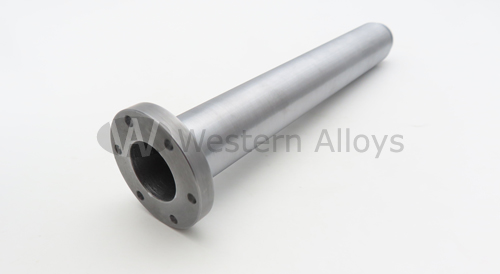

The alloy is generally used in the double annealing state, but also can be strengthened by solution aging, and its main semi-finished products include sheet, bar, pipe, fasteners, extruded profiles and forgings.

The advantages of TC18 Titanium rod in terms of hardenability and comprehensive performance are determined by its unique phase transition and microstructure characteristics. Compared with the original microstructure of the rod, the microstructure after quenching at 750℃ is slightly increased in the amount of medium axis a phase, and the number sensitivity of sheet a phase is significantly reduced, and the sheet a phase completely disappears when the temperature rises from 1 to 850C. When the overflow above the phase transition point is treated, it is a single coarse β phase.

The microstructure of the alloy under furnace cooling is different from that of water cooling and air cooling. At lower temperature, the equiaxis gradually changes to polygon, and most of the a phase becomes elongated at 850℃, and the number also increases slightly. The complete Weil structure was obtained by heating above the phase change point.

TC18 Size Supplied

|

Our products can apply to GB/T 3621, GB/T 2965, GB/T 3623, ASTM B265, ASTM B348, ASTM B338, ASTM B863 and other standards.

The product can be tested by micro-structure to reach acceptable structure According to ASTM E112-13 standard.

Conduct detection can be according to GB/T5193-2020 or customers' requirements.